| |

|

| |

|

|

|

| |

|

| |

|

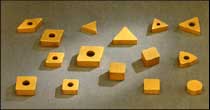

SX5

Si3N4

Type

•

SX5 is a composite ceramic cutting tool material developed for high

speed macnining of nickel based alloys. SX5 is capable of machining

materials such as Inconel 718 (45RC) at speeds up to 10 times faster

than carbide. SX5 shows excellent notching resistance.

Applications

•

Rough finish turning Ni-based alloys.

• Milling of Ni-based alloys.

|

|

SX1

Si3N4

Type

•

SX1 is an extremely wear resistant silicon nitride ceramic, sintered

by a special HIP process. SX1 combines both toughness and wear resistance

especially in applications where casting sand is encountered.

Applications

•

Rough finish turning of gray cast iron.

• Milling of gray cast iron.

|

|

SP1,

SP2 Si3N4

Type

•

Both SP1 and SP2 are extremely pure grades of silicon nitride. The

multi-coated ceramic gold coating extends tool life over a broad

speed range of cutting speeds and makes edge wear easily detectable.

Use SP1 for higher speeds and where more toughness is needed.

Applications

•

Rough and finish turning ductile and gray cast irons.

|

|

SX8

Si3N4

Type

•

SX8 is our toughest silicon nitride ceramic. This material is sintered

by a special HIP process that combines both toughness and wear resistance

for longer tool life. Designed for use on gray cast iron, SX8 is

a perfect choice for both high speed interupped rough turning and

milling. SX8 can be used with or without coolant.

Applications

•

Rough turning and milling of gray cast iron.

|